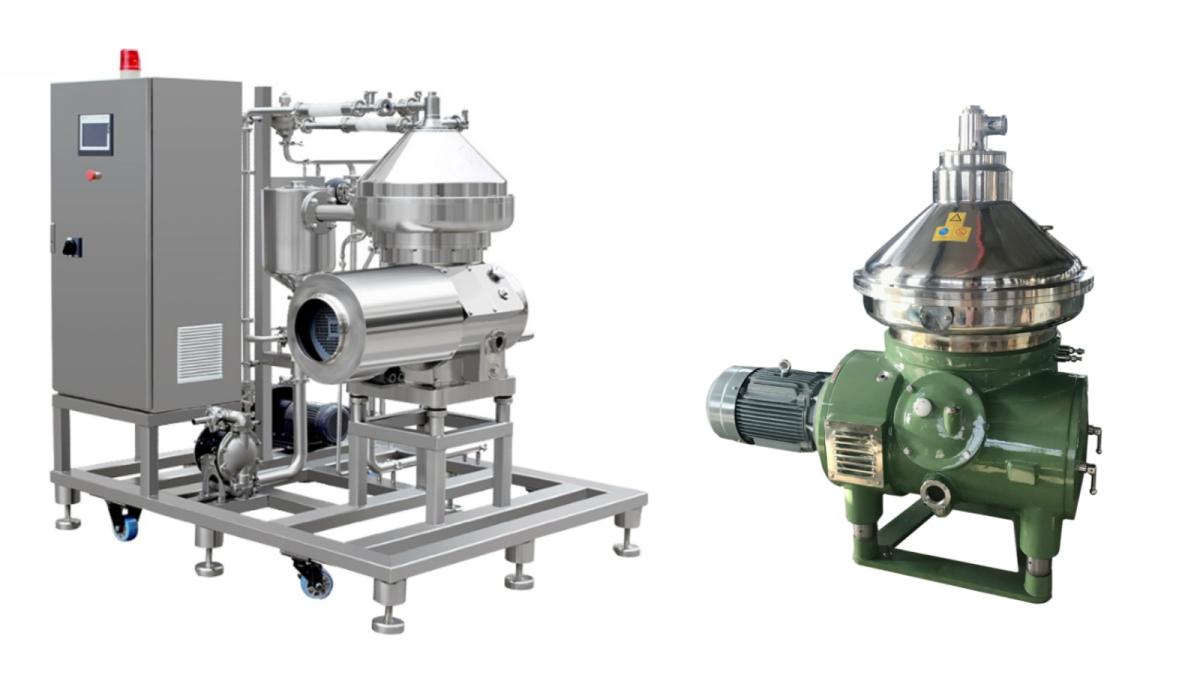

Product Description

Disk stack centrifuges are high-speed centrifuges for the mechanical separation and clarification of mixtures comprising solids and liquids. These machines can be used in a wide range of applications. Due to their special design, disk stack centrifuges work at a higher rotation speed than other centrifuges such as decanters. As a result, the centrifugal acceleration (g-force) generated by a disk stack centrifuge is significantly more powerful than in decanter centrifuges. Moreover, the disks included provide a large clarifying area. Thus, it is possible to separate ultra fine solid particles from a liquid and to separate liquid mixtures in an efficient way

Power drive adopts the friction clutch, Transfer power by the fluid, start reliably, prevent overland. The bearings used the machine are SKF grade in Sweden., guarantee working precision of the machine.

The separator adopts the PLC automatic control system, can carry out automatic de- slugging, ability of fitness is stronger, automatic degree is high. Easy to adjust, worker labor strength is opposite to ease, the solids content ratio in the mixture fluid is widely.

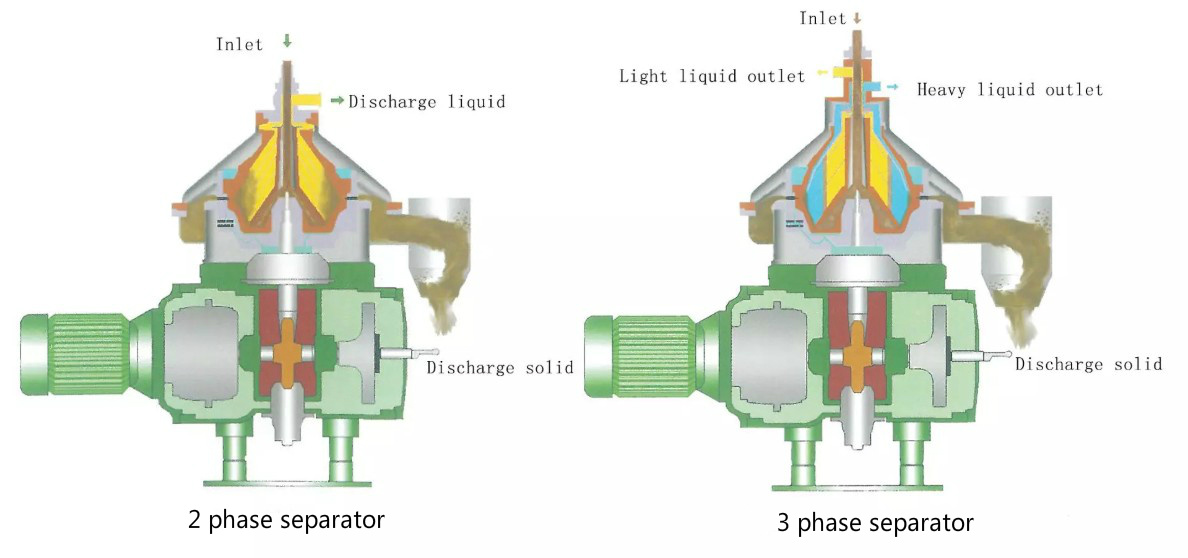

Schematic diagram

Technical parameters

The mixture fluid to be processed are fed to the bowl from feeding pipe ,under the effects of centrifugal force, the solids which has heavier density collects on the bowl wall .it include jams and impurities ,collected in sediment holding space .After a while ,the separated soilds are ejected from the bowl at controlling of PLC .the intervals at which de-slugging have to take place depend on the quality of the mixture fluid .De-slugging include automatic de-slugging ,total de-slugging ,partial de-slugging ,Normally customer don't need total de-slugging ,put up partial de-slugging under the condition of effects of automatic de-slugging are bad .the interval between two partial de-slugging is up to two minutes ,and electric current is normal .then re-establish the automatic de-slugging interval .The lighter products (lower density )flow along the inner side of the discs into the passage in the upper distributor ,the lighter product is discharged from the machine by the centrifugal pump .Thus the mixture fluid is separated well ,the centrifuge adopts self de-slugging and centripetal pump .Thus the machine can work continuously for a long time ,attain good separation effects in long run.