This article explores the key benefits, selection criteria, and market trends for bioreactor-based algae production, helping manufacturers make informed procurement decisions.

1.What is a Bioreactor Algae System?

A bioreactor algae system is a controlled environment designed to optimize algae growth using advanced photobioreactor (PBR) or fermenter-based technology. Unlike traditional open-pond systems, bioreactors offer precise control over key growth parameters, including light, temperature, pH levels, and nutrient supply. Bioreactor Algae systems provide a controlled environment ideal for enhancing algae cultivation through advanced photobioreactor (PBR) or fermenter-based technology. As opposed to conventional open-pond systems, bioreactors enable meticulous regulation of crucial growth factors such as light, temperature, pH levels, and nutrient provision.

Types of Algae Bioreactors:

- Photobioreactors (PBRs) – Use light to facilitate photosynthesis, ideal for microalgae cultivation in biofuels, cosmetics, and pharmaceutical applications.

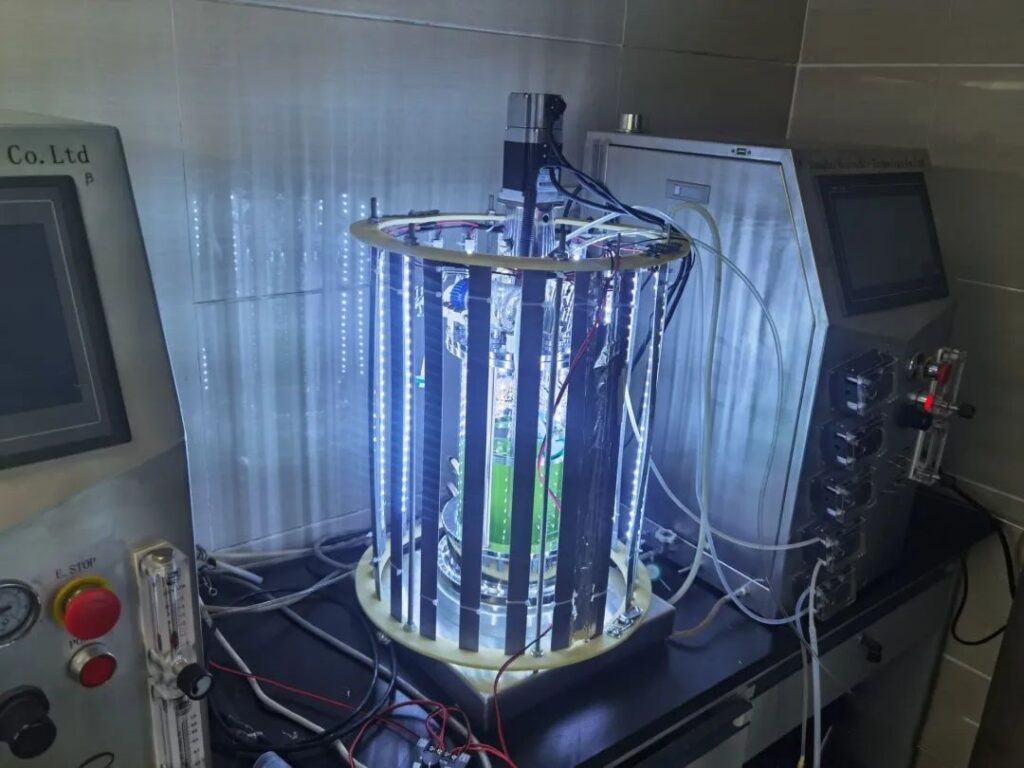

Bailun 10L glass photobioreactor BLBIO-GJL - Heterotrophic Bioreactors – Utilize organic carbon sources instead of light, suitable for large-scale algae production in controlled environments.

- Hybrid Systems – Combine both phototrophic and heterotrophic methods for maximum productivity and adaptability.

2.Why Manufacturers Need Bioreactors Algae?

2.1. High Yield and Productivity

Compared to traditional algae cultivation, bioreactors improve biomass productivity by up to 10 times, ensuring higher yields in a smaller footprint. Manufacturers benefit from consistent, high-quality microalgae production with fewer external risks, such as contamination and environmental fluctuations.

2.2. Enhanced Process Control for Consistency

In industries like pharmaceuticals, nutraceuticals, and biofuel production, maintaining a consistent algae strain and biochemical profile is essential. Bioreactors allow precise control over growth conditions, ensuring reliable and repeatable results.

2.3. Scalability for Industrial Applications

Modern bioreactor systems are designed for scalability, enabling manufacturers to expand production efficiently. Whether starting with a pilot-scale bioreactor or a full-scale industrial facility, modular designs ensure seamless growth.

2.4. Sustainable and Eco-Friendly Production

Bioreactor-based algae cultivation is a sustainable alternative to traditional biomass production. Many industries use algae for:

- Carbon capture and CO₂ reduction

- Biofuel production as a renewable energy source

- Natural food coloring and protein sources

For manufacturers aiming to meet sustainability goals, investing in closed-system algae bioreactors reduces land use, water consumption, and carbon emissions.

3.Key Considerations When Choosing an Bioreactor Algae

3.1. Growth Efficiency & Biomass Productivity

Selecting a bioreactor that maximizes algae growth rates is essential. Factors such as light intensity (for photobioreactors), CO₂ supply, and nutrient balance directly impact productivity.

3.2. System Design and Space Utilization

Manufacturers should evaluate whether a vertical column bioreactor, tubular system, or flat-panel bioreactor best fits their production space and output needs. Compact, high-density designs allow for efficient land use in industrial settings.

3.3. Energy and Operational Costs

Energy efficiency is a major consideration, especially for large-scale algae cultivation. Systems with automated light exposure, efficient gas exchange, and waste recycling help reduce operational costs.

3.4. Contamination Prevention and Maintenance

Bioreactors with sterile, closed-loop designs prevent contamination, reducing the need for antibiotics or chemical treatments. Features such as automated cleaning, real-time monitoring, and remote control capabilities improve maintenance efficiency.

3.5. Compliance with Industry Standards

For manufacturers in pharmaceutical, nutraceutical, and food industries, ensuring compliance with GMP (Good Manufacturing Practices), FDA, and ISO standards is crucial. Choosing a bioreactor with traceability and documentation features simplifies regulatory approval.

4.Industry Applications of Bioreactor-Grown Algae

4.1. Biofuels and Renewable Energy

Algae-derived biofuels offer a sustainable alternative to fossil fuels. Companies in the energy sector invest in large-scale bioreactors for algae oil extraction, contributing to the development of next-generation biofuels.

4.2. Pharmaceuticals and Nutraceuticals

Pharmaceutical companies use algae bioreactors to cultivate high-value compounds such as astaxanthin, beta-carotene, and omega-3 fatty acids. These compounds are essential for nutritional supplements, antioxidants, and anti-inflammatory treatments.

4.3. Wastewater Treatment and CO₂ Sequestration

Industrial facilities integrate algae bioreactors for CO₂ capture and wastewater treatment. Algae efficiently absorb pollutants and convert CO₂ into oxygen, supporting environmental sustainability initiatives.

4.4. Food and Beverage Industry

Algae-based ingredients, such as spirulina and chlorella, are gaining popularity in the functional food market. Bioreactors ensure controlled and contaminant-free production of high-quality algae biomass for protein powders, plant-based food additives, and dietary supplements.

5.Market Trends and Future Outlook

5.1. Growing Demand for Sustainable Solutions

Governments and corporations worldwide are emphasizing green technologies, boosting investments in algae-based biofuels, bioplastics, and carbon capture solutions. The bioreactor algae industry is set to expand significantly in the coming years.

5.2. Advancements in Bioreactor Technology

Innovations such as AI-driven bioreactor monitoring, automated nutrient dosing, and genetically optimized algae strains are enhancing system efficiency. These advancements make bioreactors more cost-effective and scalable for industrial applications.

5.3. Expanding Applications in Biotech and Pharma

The pharmaceutical and biotech industries are increasing their reliance on bioreactor-grown algae for drug development and research. With the rise of personalized medicine and plant-based biopharmaceuticals, the demand for high-purity algae compounds continues to grow.

6.Choosing the Right Bioreactor Algae Supplier

For manufacturers looking to invest in bioreactor algae systems, selecting a reputable supplier is critical. Consider the following:

- Experience in large-scale algae cultivation solutions

- Customization options for specific industry applications

- Technical support, training, and after-sales service

- Compliance with regulatory standards

A strong partnership with a trusted bioreactor manufacturer ensures a smooth integration process and long-term success in algae production.

结论

Bioreactor algae cultivation represents the future of industrial algae production, offering a sustainable, high-yield, and scalable alternative to traditional methods. For manufacturers in biofuels, pharmaceuticals, food, and wastewater treatment, investing in an bioreactor algae system delivers both economic and environmental benefits.

By choosing the right bioreactor technology, optimizing growth conditions, and staying ahead of industry trends, manufacturers can harness the full potential of bioreactor-based algae production for long-term profitability and sustainability.

Looking for a High-Performance Bioreactor Algae System?

Contact us today to explore customized bioreactor solutions for your manufacturing needs.