The Cornerstone of Biotech Production

Fermentation processes occasioned by a range of activities such as the production of pharmaceuticals, food and beverages all require stainless steel bioreactors in the ever-evolving biotechnology industry. They allow the researcher to control the environment including temperature, pH and oxygen that makes it ideal for microbial, cell and plant cultures. Stainless steel bioreactors are well-known in companies related to fermentation due to their strength and compatibility with large-scale production.

In this article, we’ll delve into the specifications, advantages, and uses of the stainless steel bioreactors as well as discussing Sartorius bioreactors and stainless fermenters, and the current emerging technologies in the field of bioreactors.

What Are Stainless Steel Bioreactors?

A stainless steel bioreactor is a container that is used in biotechnology to produce valuable products with the help of cells or microorganisms. The main material used in the construction of these bioreactors is stainless steel to enable the bioreactors to withstand corrosion, high temperatures, and pressure that is characteristic of the production processes. In the bioreactor there are strict conditions maintained for cultivation of cells or microorganisms and for their intensification.

In layman’s terms, the stainless steel bioreactors are the ideal environment for large-scale fermentation processes to take place and maintain conditions that facilitate biosynthesis required for products like antibiotics, vaccines, enzymes, and bio fuels amongst others.

Key Features of Stainless Steel Bioreactors

The construction of stainless steel bioreactors makes them suitable for the large-scale production used in the biotech industries. Here’s why:

Corrosion Resistance

Iron status of the stainless steel bioreactors is highly conspicuous because of its resistance to corrosion. Stainless steel cannot contaminate the biological products, which is highly essential for bioproducts production, and this makes stainless steel to be a plus. In fermentation processes, there are changes in pH which may corrode other materials such as glass or plastic. These bioreactors are made using stainless steel and are therefore capable of withstanding such harsh conditions in the long run.

Thermal Stability

Temperature plays a crucial role in the growth of microbes and the formation of the product. Due to the properties of stainless steel, the bioreactor can control the temperature to keep the cells or microorganisms in the best condition to produce efficiently. They possess sophisticated cooling as well as heating jackets for this purpose.

Scalability

In contrast to the laboratory vessels, it is possible to scale-up the stainless steel bioreactors to fit the large-scale production requirements. Since they can accommodate a lot of culture media and microorganisms they are suitable for commercial production.

Durability and Long Lifespan

According to past performances, stainless steel is one material that is characterized by high strength and toughness. Stainless steel bioreactors are built to sustain the pressures of high-performance, continuous usage and this makes it worthwhile for any company which is seeking to purchase equipment that will serve for the longest time.

Ease of Sterilization and Cleaning

A highly important factor to consider in the industry since biotechnology processes entail handling of products that may be sensitive to contamination. Stainless fermenters can be easily sanitized so as to avoid infections of other batches of the product. Non-porosity of their surfaces and the presence of welded joints make them easy to clean with little chances of bacterial or fungal formation.

For further details, visit BaiLun Bio’s Stainless Steel Bioreactor.

Applications of Stainless Steel Bioreactors

Stainless steel bioreactors are used in almost every related industry, and are not limited to pharmaceutical industries only, but also food industries. Let’s take a look at some of the most important spheres that use such bioreactors:

Pharmaceuticals and Biopharmaceuticals

Stainless steel bioreactors are essential in manufacturing pharmaceutical products and especially developing biologic drugs such as vaccines, monoclonal antibodies, therapeutic proteins amongst others. It entails running mammalian or bacterial cells which synthesize the API in a controlled environment.

These bioreactors also contribute to the high-quality manufacture of the essential medicines by providing a suitable culture for the growth of the cells. The industry applies large stirred-tank stainless fermenters in these applications because they can accommodate high cell densities and intricate processing.

Food and Beverage Production

In the food industry, stainless steel bioreactors are used in the production of such products as yogurt, cheese, wine and beer among others. The controlled fermentation is very crucial in the production to avoid any qualities that could affect the taste and texture of the food product. In breweries for instance, yeast cultures are propagated in stainless steel bioreactors so that the right fermentation environment for brewing beer is achieved.

Additionally, stainless fermenters are also used on occasions in the dairy fermentation procedures aimed at producing cultured milk products such as kefir, buttermilk and cream.

Biofuels Production

There is a great demand for renewable energy sources and through steel bioreactors biofuels are produced through this modern equipment of stainless steel. For example, yeast or bacterial species are grown in stainless steel bioreactors from agricultural residues, or sugar to produce biofuel like ethanol, biodiesel.

Since the fermentation process requires certain temperatures, pH and oxygen levels to be maintained, these bioreactors enable the process to be efficiently conducted and to produce high efficient bio fuels used in industries and transport.

Wastewater Treatment

Stainless steel bioreactors are also employed in water treatment plants where there is the use of microorganisms in the degradation of organic compounds in water. Thus, the they are effective and durable for use in this setting to help scale up the biological processes that are used in treating industrial and municipal wastewater.

Advantages of Stainless Steel Bioreactors

Superior Durability and Longevity

This is due to the fact that stainless steel bioreactors are extremely durable in nature. In contrast to failure or breakage of glass or plastic materials which can easily be caused by pressure, stainless steel can withstand very high pressure and heat without any sign of failure. This attribute makes it possible for them to be used for long periods and therefore they do not need frequent replacement.

Reduced Contamination Risk

Another advantage of using the stainless steel bioreactors in the production of biopharmaceuticals and food products is because it has less chances of contamination. The material also does not corrode which means no unwanted reactions occur that would lead to contamination of the products. These deep-drawn vessels as well as the welded seams also reduce the likelihood of bacteria or fungi growing on the bioreactors making fermentation processes safe and clean.

Efficiency in Large-Scale Production

In large-scale production, industries require large volume bioreactors that should be highly efficient in their operations. Stainless fermenters are used to produce large volumes of culture media or cells, and this makes stainless steel bioreactors vital to processes such as manufacturing drugs or bio fuels.

Low Maintenance Costs

Besides the initial high costs, the material used in fabrication of stainless steel bioreactors is resistant to wear and tear thus it has minimal maintenance costs. This makes them a good option for any firm that would wish to invest in items that would not require constant replacement or repair in the future.

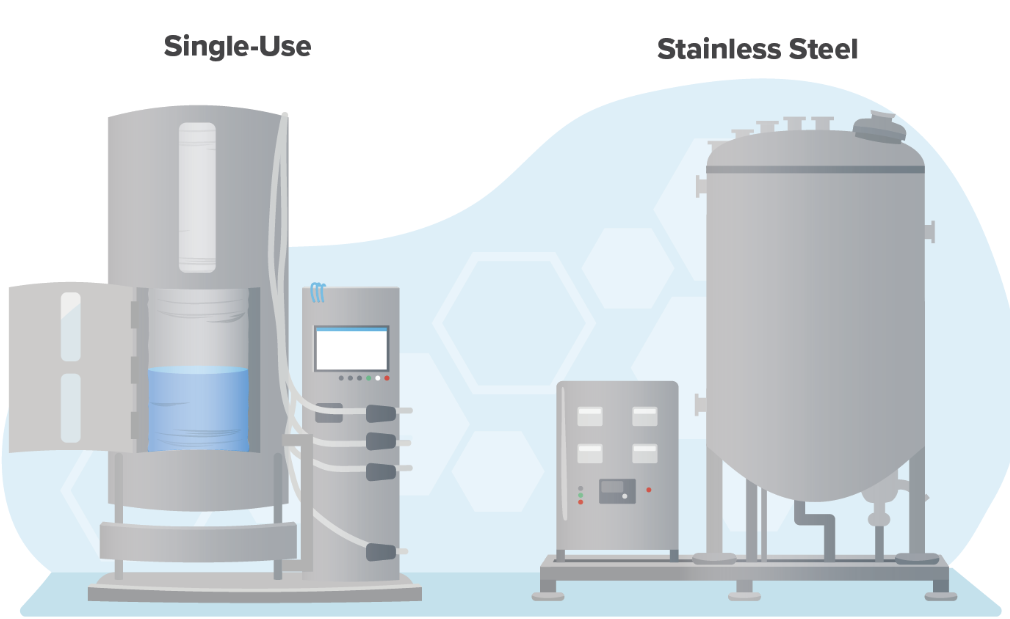

Differentiating Stainless Steel Bioreactors from Other Fermenters

There are a number of options when it comes to selecting the bioreactors that the industries can use and this depends on a number of factors such as cost, scalability and how they can be maintained. Below are some of the comparisons between stainless steel bioreactors with other possibilities such as glass and plastic fermenters.

| Feature | Stainless Steel Bioreactors | Glass Bioreactors | Plastic Bioreactors |

| Durability | High durability, long lifespan | Fragile, prone to breakage | Moderate durability |

| Cost | Higher upfront cost, but cost-effective in the long run | Lower cost, limited scalability | Lower cost, limited scalability |

| Scalability | Excellent for large-scale production | Limited scalability | Limited scalability |

| Sterilization | Easy sterilization and cleaning | Difficult to sterilize | Easy sterilization |

| Maintenance | Low maintenance, long-term investment | High maintenance | Moderate maintenance |

Future of Stainless Steel Bioreactors

Taking into consideration the needs for more biologics, biofuels, and other bio-derived products in the near future, it is safe to say that the future of stainless steel bioreactors is rather promising. Technological factors such as digital controls, automation and real time monitoring systems are the major factors that are enhancing productivity levels.

Further, advancement in Sartorius bioreactors/other emerging bioreactor systems are expected to minimize the environmental impact of the fermentation process. Such advancements will likely go on contributing to the improving use of stainless steel for bioreactor production, thus establishing the material’s applicability and effectiveness for future uses.

Conclusion

In conclusion, stainless steel bioreactors are very crucial in the current world of biotechnology. That is why vertical autoclaves are the most popular and suitable for various industries, from pharmaceuticals to food production, due to their strength, scalability, and suitability for providing steady and controlled conditions. As for the latter, there are many modern variations such as Sartorius bioreactors, however, stainless steel bioreactors are still considered to be the most standard for fermentation at industrial scale.

For those companies seeking a quality bioreactor in stainless steel or information on fermentation equipment, BaiLun Bio has products to fit the various needs of industries.