What is a homogenizer?

Homogenizer is a device that is used to emulsify substances in order to make this mixture uniform in composition. Homogenization of the particles is carried out in this process to ensure that they are well distributed and uniformly arranged in the product to enhance stability, texture and quality of the final product. Homogenizer machines are applied in food processing, pharmaceutical industries, cosmetic industries, and biotechnology industries since consistency is essential in the production process.

The work of homogenizer mixers is to make certain ingredients of a material to be equally blended and therefore it is used in the processing of milk and formulation of various drugs such as drug suspension. But the questions that will be of interest to the people are; how does it operate and what’s the type of EHSMSs? In this article, we will try to describe the principle of operation of homogenizers and their uses.

The Science Behind Homogenization

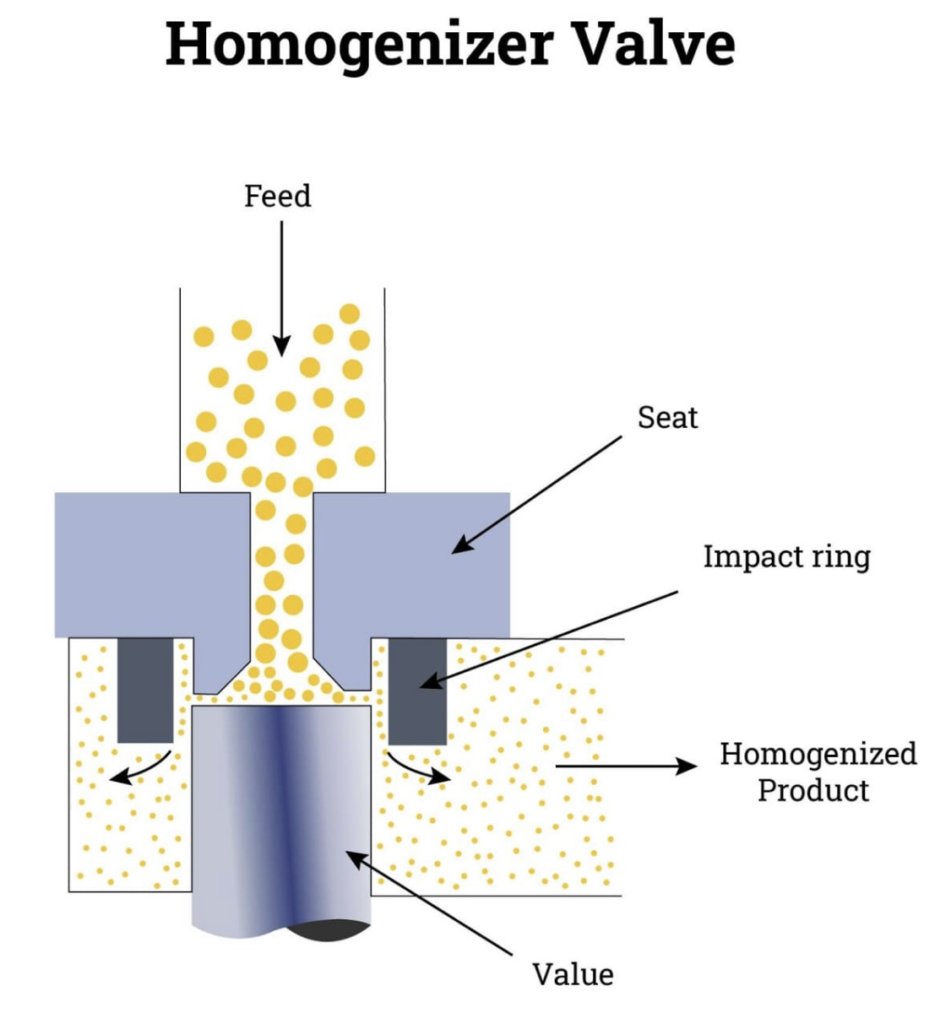

Homogenization is a process whereby an agglomeration of large particles is disintegrated and suspended uniformly throughout a liquid or a semi-solid substance. This leads to fully stable and consistent mixtures and does not separate over time. The essence of this process is to use pressure and/or shearing forces or ultrasonic vibrations to arrive at the right particle size distribution.

In a homogenizer, particles are passing through the latter space under high pressure and the process results in turbulence and cavitation. This action is done to disperse larger particles within the medium and thus ensuring that they do not settle and affect the texture of the final product. These machines can also be designed to include features that regulate the temperature in case of incorporation of heat sensitive parts.

Types of Homogenizers

It is necessary to note that depending on the industry, there are specific homogenizer machines that are suitable to be used. Here are what there are more commonly:

1. High-Pressure Homogenizer

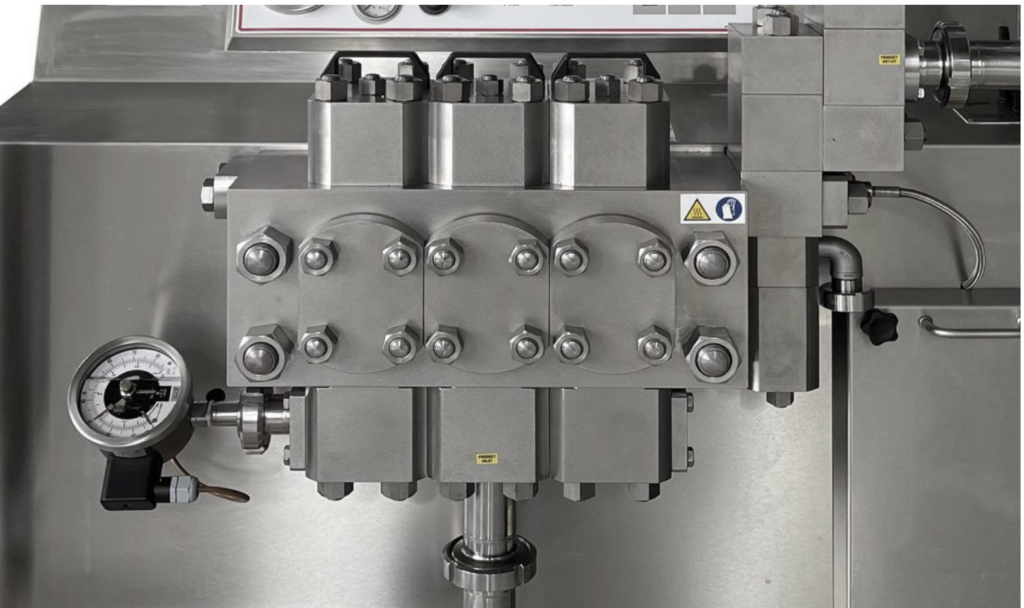

- Manifests very high pressure to reduce and blend substances at an atomic level.

- Ideal for dairy processing, pharmaceuticals, and cosmetics.

- Produces stable emulsions and suspensions with uniform texture.

2. Ultrasonic Homogenizer

- Ultrasonic waves of high frequency are used to disrupt particles and mix them with other particles.

- Small scale usage is often in laboratory tests and experiments as well as in different small scale uses.

- Ideal for cell disruption, nanoparticle synthesis, and sample preparation.

3. Mechanical Homogenizer Mixer

- Specifically, it employs the use of rotating blades or paddles for blending the materials in a very efficient manner.

- It is commonly employed in the food and chemical industry.

- Available in batch and continuous operation models.

4. Bead Mill Homogenizer Machine

- Uses beads on the physical method of grinding and dispersion of the materials.

- Useful in disaggregation of hard and complex cells in the field of biotechnology.

- Ideal for DNA/RNA extraction, pharmaceutical formulations, and microbiology applications.

Depending on the type of food products to be homogenized, the appropriate homogenizer is used since each type has its strengths when used for specific tasks.

Key Applications of Homogenizers

There are many reasons why companies across different industries cannot do without these machines. To better understand how these four types of words are employed, let us have a closer look at them.

1. Industria de alimentos y bebidas

- Milk Processing: It helps not to allow cream formation on the top and texture enhancement.

- Juice Production: It helps to maintain a consistent texture and durability in the product.

- Seasoning and Dressings: It helps to gain a uniform texture and also to improve the stability of the product.

2. Pharmaceutical Industry

- Drug Formulation: Enhances bioavailability and absorption of active ingredients.

- Vaccine Production: Ensures even dispersion of crucial components.

- Ointments and Cream: Makes good formation of products that are easy to apply.

3. Cosmetic and Personal Care Industry

- Lotion and Cream Manufacturing: Ensures a silky texture and consistency.

- This method enhances the durability of the perfume and its effectiveness by helping it to emulsify.

- Sunscreen Production: Ensures even distribution of UV-blocking agents.

4. Biotechnology and Research

- Cell Lysis: Extracts DNA, proteins, and other biological components.

- Nanoparticle Synthesis: Produces materials for targeted drug delivery.

- Sample Preparation: Aims at preventing contamination and ensuring that right samples are tested on in order to produce accurate results.

This way, industries will be in a position to appreciate the uses of these mixers in enhancing the efficiency and quality of mixtures.

Advantages of Using a Homogenizer

There are many advantages associated with the use of a homogenizer machine as highlighted by the following facts:

- Reduced Scaling: Reduces the chances of formation of large crystals or scale like structures.

- Increased product shelf stability: By stopping separation of the products, their shelf life is also boosted.

- Increased Bioavailability: Allows better absorption of active ingredients in pharmaceuticals.

- Microbial Reduction: It assists in enhancing safety of foods by distributing preservatives throughout the food items.

- Efficient Processing: Reduces production time and energy consumption.

These benefits of homogenizers make the equipment necessary for industries that demand quality, high performance, and uniformity of products.

Choosing the Right Homogenizer Machine

Choice of homogenizer depends on several factors as follows;

1. Application Needs

- This is because there is the high-pressure homogenizer mixer, the ultrasonic one, and the mechanical one.

- As will be explained below, it is necessary to know whether the machine is dedicated for use in the manufacturing of food products, medicine or cosmetics or for research purposes only.

2. Capacity Requirements

- It is therefore important to select between laboratory scale and industrial scale homogenizer machines.

- The next condition is to make sure that the production volume that the machine is required to handle is sufficiently met.

3. Pressure and Speed Considerations

- Pressure increases directly affect the fineness of the dry powder since finer particle size is produced when pressure is increased.

- The speed settings should depend on the viscosity of the material and the time required for the process.

4. Material Compatibility

- Check the type of materials you are to blend and determine if it is appropriate for the homogenizer you intend to use.

- The specifications to look out for includes chemical resistance and durability of the pipe.

5. Maintenance and Cost Factors

- The other two factors that should be considered are ease of cleaning and spare parts availability.

- In other words, minimize cost at the start of a project but at the same time avoid compromising on efficiency in the long-term operation of the project.

The selection process of these machines should enable the achievement of maximum efficiency and quality of the resulting product.

Common Challenges in Homogenization

As much as homogenizer mixers have been established to have their advantages, they also pose some drawbacks as follows;

- Energy Intensive: Some of the homogenizers are associated with high power consumption.

- Maintenance Requirement: It requires annual, biannual, monthly, week and daily servicing and cleaning.

- Some materials are sensitive to shear stress meaning that some of the compounds in the material may break down under pressure.

- Expensive Equipment: Avanzado homogenizer machines are expensive and so one should be very careful when buying the machines.

Knowledge of these challenges assists industries in the reduction of risks associated with homogenization procedures when handling their products.

Future Trends in Homogenizer Technology

There is the need to create more of these kinds of mixers in the market. Some emerging trends include:

- Automation and AI Integration: Smart sensors for real-time process monitoring.

- Sustainable Processing: Energy-efficient designs and eco-friendly materials.

- Improved Nanotechnology Applications: Enhanced nanoparticle production for pharmaceuticals and biotechnology.

- Customization and Modular Designs: Adaptable homogenizer machines for various applications.

These innovations are said to have the potential of causing a revolution in the industry and the efficiency of homogenization.

Conclusión

A homogenizer is an essential piece of equipment in many industries including the foods industry, the pharmaceuticals industry as well as the cosmetics industry. No matter whether it is a homogenizer mixer used for mixing up various products or a homogenizer machine used for reducing the particle sizes, the knowledge of the working principle and application of this equipment will be useful.

Proper purchase of homogenizer leads to a higher product quality, product stability and increase in rate of production. Thus, the prospects for further development of homogenizers are rather favourable, with new developments aimed at increasing efficiency and environmental friendliness. It is therefore clear that when selecting a specific homogenizer machine amongst the various brands available in the market, it will help firms get better results, improve the quality of their products and consequently become more competitive in their respective fields. Contáctenos for more detail!