Characteristics Of Industrial Fermenter

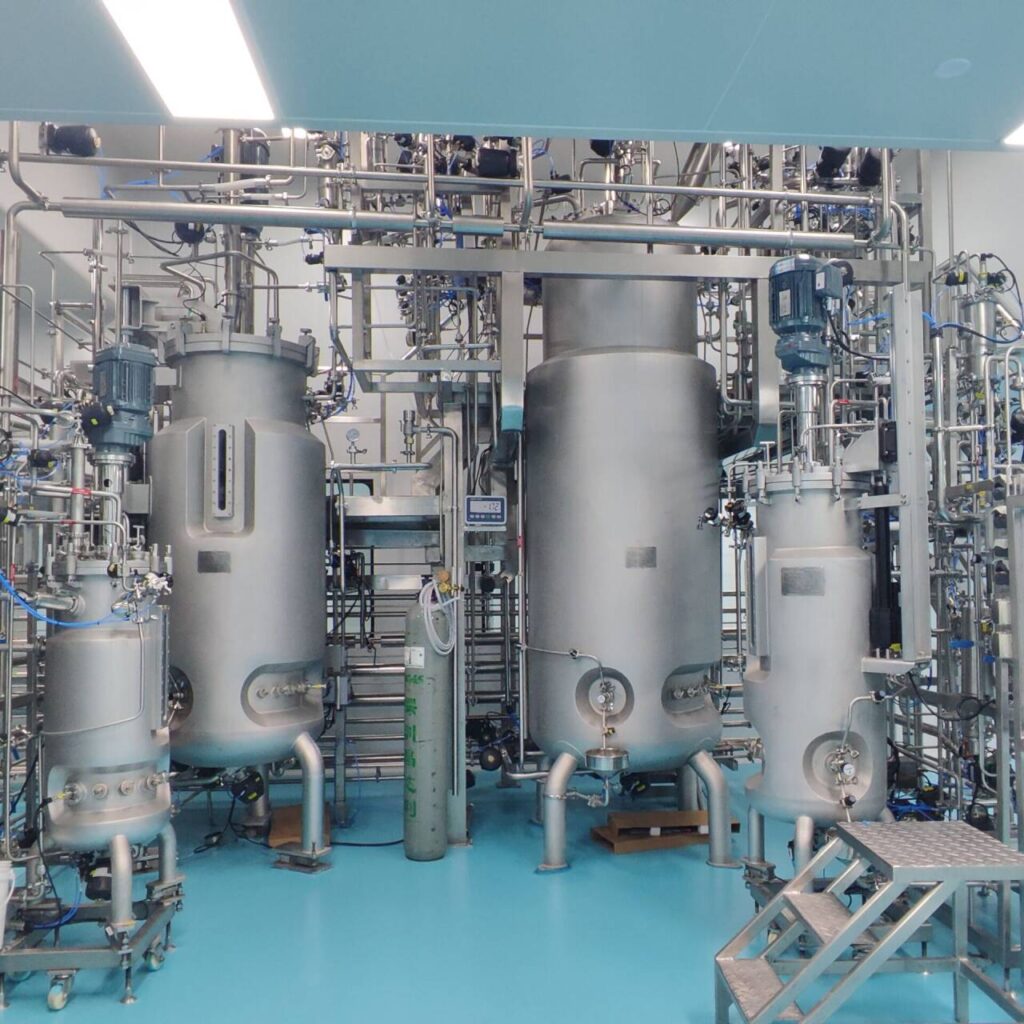

Industrial fermenter refers to the device used for microbial fermentation in industry. Industrial fermenter is the most important and widely used equipment in fermentation equipment. It is the heart of the fermentation industry and the bridge connecting raw materials and products. The full volume of commonly used fermentation tanks in laboratories is usually between 2 liters and […]