Revolutionizing Bioprocessing with Efficiency and Precision

Essentially, fermentation is an incredibly vital process in the field of biotechnology where several products which include pharmaceuticals, bio-fuels, food and beverages can be manufactured. Of all the fermenters applied in such processes, the airlift fermentor can be named one of the most effective, manageable, and suitable for imparting ideal conditions for microorganisms. For those who are considering the possibility of an airlift bioreactor, or even wondering about the airlift meaning in relation to fermentation, this article provides all the information that will be useful.

What is an Airlift Fermentor?

A fermentor is a bioreactor that is used for the cultivation of microorganisms in a controlled environment for the purpose of producing different commodities. The airlift fermentor for instance is a bioreactor that employs the airlift technique in reducing its culture medium in a manner that will allow enough aeration and mixing without using any impellers. This is different from the other common fermenters, like the stirred-tank bioreactors, in that it incorporates a specific feature.

In other words, in the airlift fermentor, the circulation within the culture medium is carried out by air or gas making it effective to support the growth of microorganisms. This method is widely used in both laboratory and large-scale processes due to its benefits which is a high yield coupled with low energy requirement.

Understanding the Airlift Bioreactor

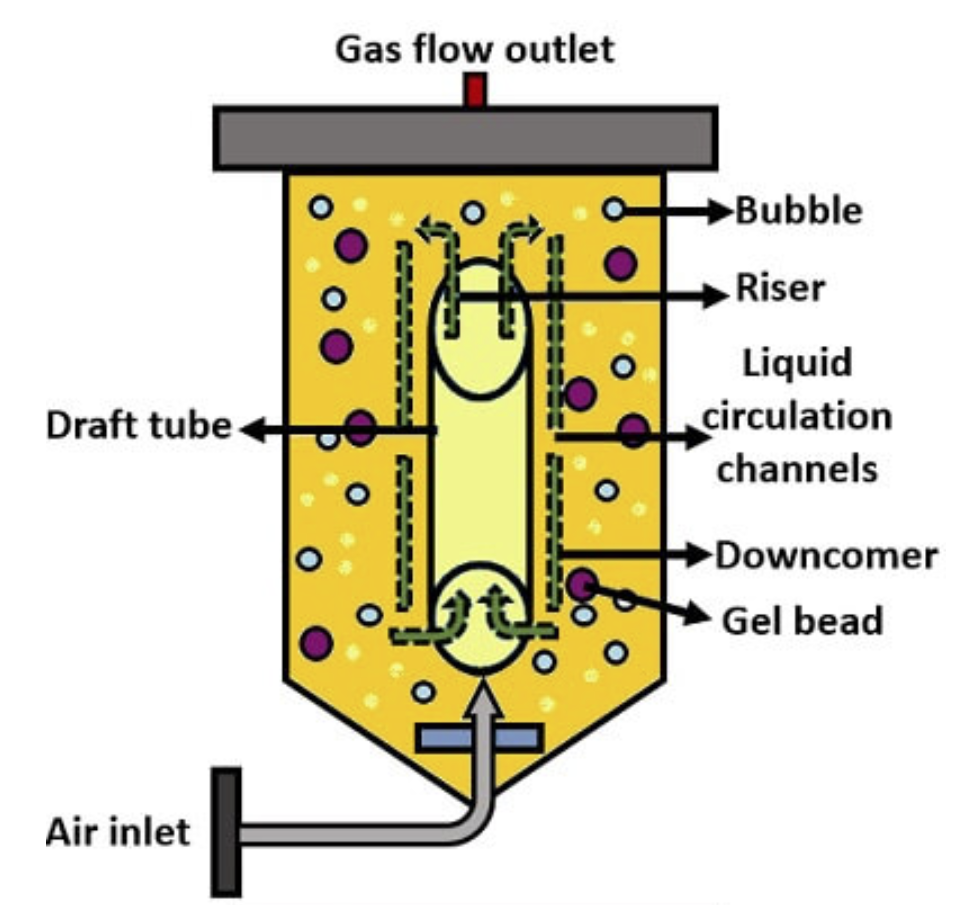

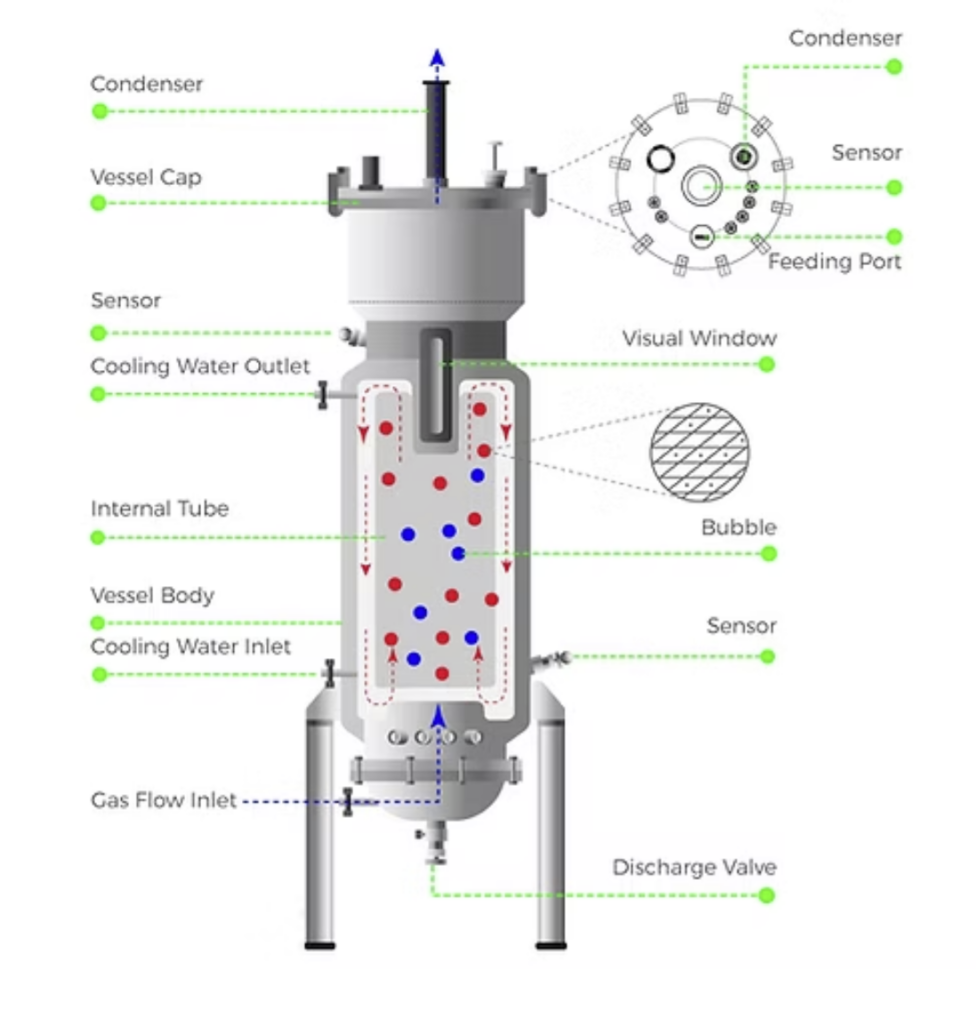

The airlift bioreactor works based on the concept that it contains two regions in the fermentor, that is the riser and the downcomer. These zones are obtained when air or gas is supplied at the bottom of the fermentor. This injected air results in formation of bubbles which rise through the culture medium in the riser thereby causing the movement of the culture medium. With the help of these bubbles, the liquid also rises along the bubbles, which results in a slow circulation that aids in mixing and exchange of gases.

After the air rises up to the top of the fermentor, it proceeds to the downcomer in which the liquid flows downwards. This makes it possible to nurture the delicate cells in the body without exerting a lot of shear forces to the cells.

Key Components of an Airlift Fermentor

One has to understand that an airlift fermentor is effective due to these parts:

- Gas Distributor: A gas distributor is also fixed at the lower end of the fermentor to spread gases such as air for blending throughout the fermentor. This helps in creating bubbles of the same size, which helps in the good mixing process and also in the transfer of oxygen.

- Riser and Downcomer: Downcomer and Riser are two of the zones that are effective in developing the circulation pattern. The riser is designed to allow the culture medium to rise along with the gas bubbles while the downcomer is used to enclose the liquid and make it flow downwards carefully.

- Draft Tube: The airlift fermentors may also contain a draft tube that segregates the riser from the downcomer section. This leads to better contact area between the gas and the liquid phases and in turn enhances oxygen transfer as well as the general performance of the fermentation process.

- Vent: It is the part of the system from where the fermentation gases are released out. It is normally mounted at the upper region of the fermentor so that the removal of the excess gas does not affect the circulation.

The Science Behind Airlift Technology

In order to understand the airlift meaning it is crucial to appreciate the rather simple but effective principle involved: the gas lift in circulation of the culture medium. What is important here is the contrast in the density of air bubbles and the surrounding fluid. When air is supplied to the fermentor, the liquid in the riser section becomes lighter as compared to the liquid in the downcomer section. This density difference is responsible for the convection moving nutrients and gases to different areas of the culture.

With passive circulation, airlift fermentors do not require mechanical agitation which is usually costly in terms of energy consumption and can introduce shear forces. This makes airlift fermentors suitable for culturing shear sensitive cultures such as animal cells or fragile enzymes that otherwise may be subjected to shear damage.

Advantages of Using an Airlift Fermentor

The advantages linked to the application of an airlift fermentor reach all the levels that are considered: efficiency level, scalability level, and usage level. It is now necessary to examine these advantages in more detail.

1. Energy Efficiency

A benefit which can be attributed to the airlift fermentor is its energy conservation characteristic. In comparison to the conventional fermenters which employ mechanical impellers for mixing of the culture media, the airlift fermentor is mixed by air or any other gas. This limits the need of extra energy in the process thus making it economical especially when applied on a large scale.

2. Low Shear Stress

Mechanical agitation in many instances leads to high shear forces that may prove very detrimental to the survival of the microorganisms. However, the airlift fermentor stirs the medium in a less strenuous manner, which is suitable for the cultures that require a non turbulent environment. This is especially essential in the growth of mammalian cells, fungi, and any other organisms that are vulnerable to mechanical impacts.

3. Scalability

It should be noted that one of the significant attributes of the airlift fermentor is that it is highly scalable. Its design makes it easy to increase from the laboratory scale to the industrial scale without diminishing performance. Regardless of the scale, you would like to carry out from a small scale to large scale fermentation, the airlift bioreactor can be made to accommodate for the desired size.

4. Uniform Mixing and Oxygenation

Good mixing of gas and liquid is required for the growth of all the microorganisms present in the system. And because of the continuous flow of the airlift fermentor, the culture medium is distributed with a fair amount of oxygen making it an efficient one. This leads to improved growth factors, efficiency, and reliability of the work done.

5. Compact Design

As has already been pointed out, the airlift fermentors are rather compact compared with other types of bioreactors, which makes them applicable for different purposes, including scientific, industrial and pilot-scale production. This design is very useful when there is constraint on the space particularly in an area with little space.

Applications of Airlift Fermentors

It is so designed that this airlift fermentor is useful in a number of industries and uses, for instance: Some notable areas include:

1. Pharmaceutical and Biotech Industries

In the pharmaceutical industry especially in the production of biopharmaceuticals including vaccines, hormones, antibiotics, and the likes, cell culture requires airlift fermentors. These delicate organisms cannot withstand turbulence and shear forces hence the need to create an environment that meets the requirements for their growth and production of the products. The two processes are delicate due to the involvement of enzymes that are very sensitive to temperature, pH, and dissolved oxygen concentration, hence the airlift bioreactors are suitable for these processes.

2. Food and Beverage Industry

In the food and beverage industry in particular, airlift fermentor is used in the manufacturing of products like beer, yogurt and wine. Oxygen transfer efficiency in these systems is very vital to the growth of yeast and bacteria which is basic to fermentation. This is because the mixing in the airlift fermentors is gentle and therefore the end product is of good quality.

3. Biofuel Production

Ethanol and biodiesel which are biofuels are made through a process known as fermentation and it involves the use of micro organisms including yeast or bacteria. Airlift fermentors can comfortably support large volumes of fermentations while at the same time sustaining the right condition for the biofuel production. These systems assist in controlling the process of fermentation to be energy efficient and capable of being expanded.

4. Wastewater Treatment

In wastewater treatment, there are certain equipment known as airlift fermentors which enable the process that campaigns for the disintegration of the organic matter. Because it isolates microbial action, these systems also enhance the rate at which solids get degraded, thus improving the efficiency of the wastewater treatment process. The low shear environment results in protection of the microorganisms used in this process hence enhancing the quality of the treatment.

Conclusion

The airlift fermentor is considered to be one of the most efficient and suitable to use in large-scale fermentation processes. Due to low shear rates, homogenizing, good aeration, and mixing capabilities needed for products like pharma, biofuels, food, and water solutions, it is suitable for several processes. Although there are some disadvantages of employing airlift fermentor like design limitations and oxygen transfer rate etc., yet it is widely preferred by the industries for fermentation processes due to low cost and high efficiency.

This is due to advancement in airlift Bioreactors and optimization of this technique hence showing the future of fermentation to be even brighter. If you are interested in how airlift fermentors can be used in your bioprocessing business, you can check it out here.